High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Innovative metrology for a wide range of applications:

- • Length and diameter

- • Surface and contour

- • Form and position

- • Gears and shafts

Precise mixing and metering of liquids and pastes:

- • Gear metering pumps

- • Pumps for fiber production

- • Meter mix dispense machines as well as mixing heads

Rotary stroke bearings for backlash-free linear and rotary movements in:

- • Mechanical engineering

- • Precision engineering

- • Optik

- • Electronics

- • and many other industries

As an internationally active company, Mahr holds its patents not only in Germany, but worldwide.

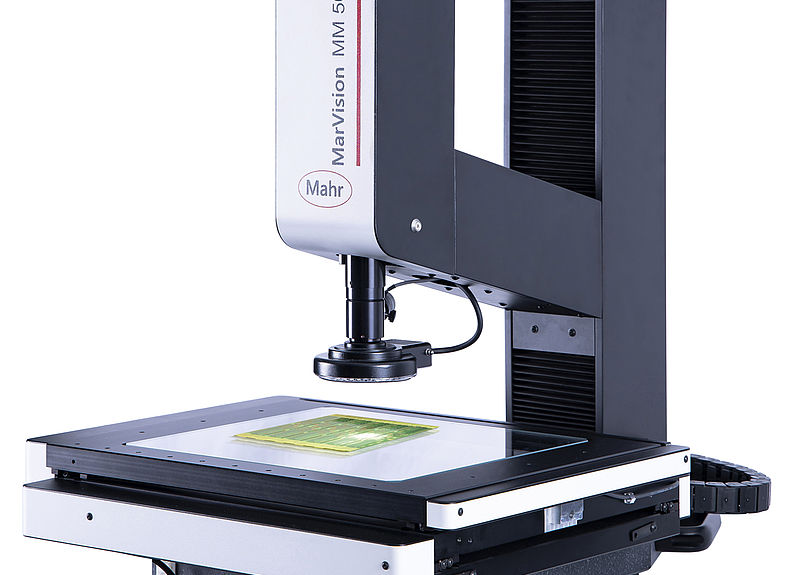

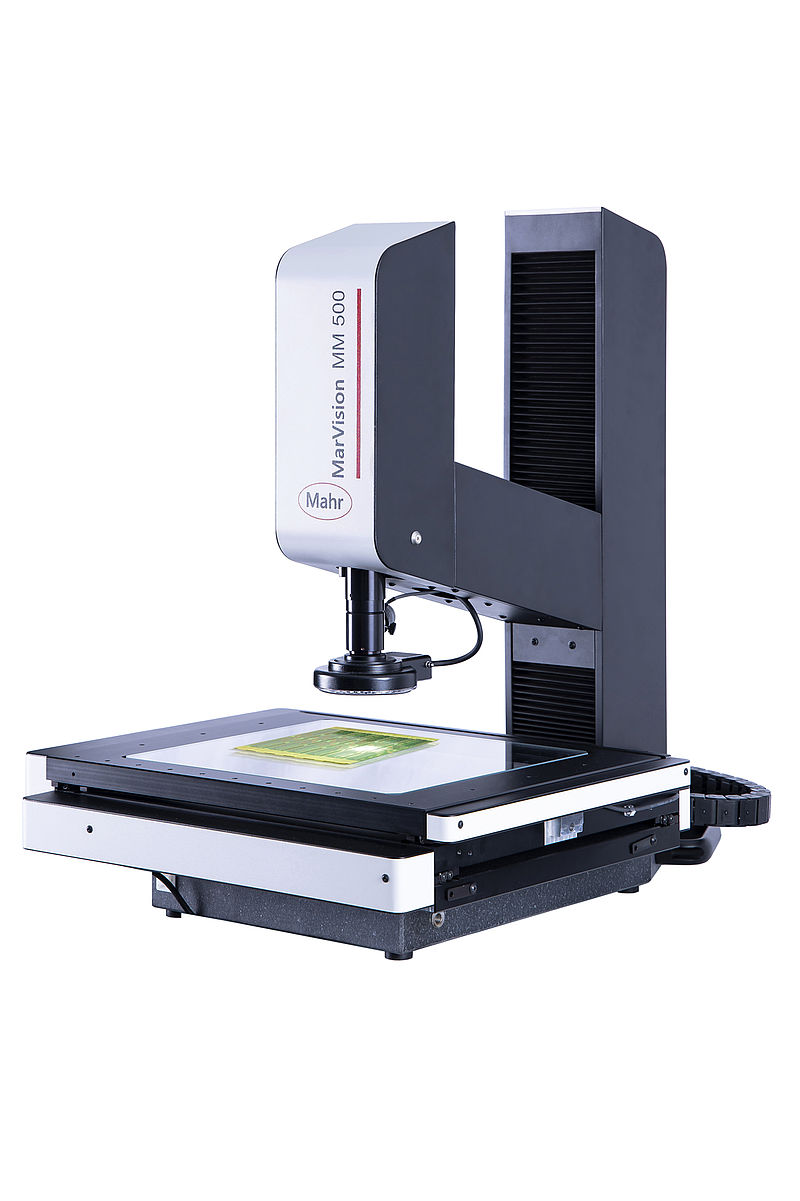

MarVision MM 500: Workshop microscope for quick evaluation of geometric elements

The MarVision MM 500 inspects, for example, turned, milled, punched and bent parts, plastic parts or electronic circuit boards. The measuring microscope uses automatic edge detection to determine geometric elements such as straight lines, circles, distances, angles or intersections on these workpieces without making contact. Thanks to the optical incremental measuring system, it offers outstanding accuracy and reliability, even with the smallest components. In addition, its color camera captures particularly high-contrast images.

Robust mechanics – intuitive control

The MarVision MM 500 has robust mechanics and a stable design that provides lasting protection against vibrations. This ensures the reliability of the measurement results. The manual models are designed to test components quickly and easily. In contrast, the CNC versions with stitching are designed for higher throughput, e.g. recurring measurement tasks on a sample. The one-box design of the electronics makes commissioning the measuring microscope very simple. Users can achieve measurement results quickly and easily without complex pre-settings: the system is controlled using the intuitive M3 software, either via touchscreen PC or keyboard and mouse.

(1,618 characters including spaces)

Source reference:

Image: Mahr GmbH

Download:

↓ 72dpi (1181 × 1772 px)

About the Carl Mahr Group

Highest precision, modern technology and international presence – that is what the name Mahr has stood for, for more than 160 years. Today, the Mahr Group, with its three business units Metrology, Mixing & Metering, and Rotary Stroke Bearings, is active worldwide in a wide range of demanding industries, such as automotive, mechanical engineering, medical technology, aerospace, optics, electronics. All products incorporate the passion and know-how of more than 1,800 employees worldwide.

Press contact at Mahr:

Severine Helmold-Deppe

Head of Marketing Communications

Tel.: +49 (551) 7073-99189

Mobile: +49 (151) 14737173

Email: presse@mahr.com

- Digimar 816 CLT: Measuring right where the action is

- MarSurf CD 140 AF: Contour measurement of individual workpieces

- Small measuring device for a large range of applications

- Millimar A 1701 M: Signal converter for automation

- Precimar SM 60-V: Combination talent for form measurements

- Control 2023: Mahr presents numerous highlights