High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Innovative metrology for a wide range of applications:

- • Length and diameter

- • Surface and contour

- • Form and position

- • Gears and shafts

Precise mixing and metering of liquids and pastes:

- • Gear metering pumps

- • Pumps for fiber production

- • Meter mix dispense machines as well as mixing heads

Rotary stroke bearings for backlash-free linear and rotary movements in:

- • Mechanical engineering

- • Precision engineering

- • Optik

- • Electronics

- • and many other industries

As an internationally active company, Mahr holds its patents not only in Germany, but worldwide.

Standard-compliant and future-proof measurement

The new ISO 21920-1, -2 and -3 profile standards for surface texture were published by the Geneva-based ISO Institute at the end of 2021 and adopted as national standards DIN EN ISO 21920-x around a year later. They combine the previous surface standards into one series of standards, but also bring significant changes. The changes include, for example:

- New terms and symbols, for example for the specification.

- The new evaluation length le, i.e. the part of the tracing distance that is evaluated. In future, it will replace the previous lm and ln.

- The nesting index Nic, Nis is also new, as the previous “cut-off wavelength” was only useful for linear filters.

- According to DIN EN ISO 21920, only a few characteristic values, such as Rz, Rp, Rv, are defined via profile sections – terms such as “sampling length” or “individual measuring section” are no longer used.

- In addition, the distinction between periodic and aperiodic profiles will no longer apply.

- And much more.

Future-oriented measurement

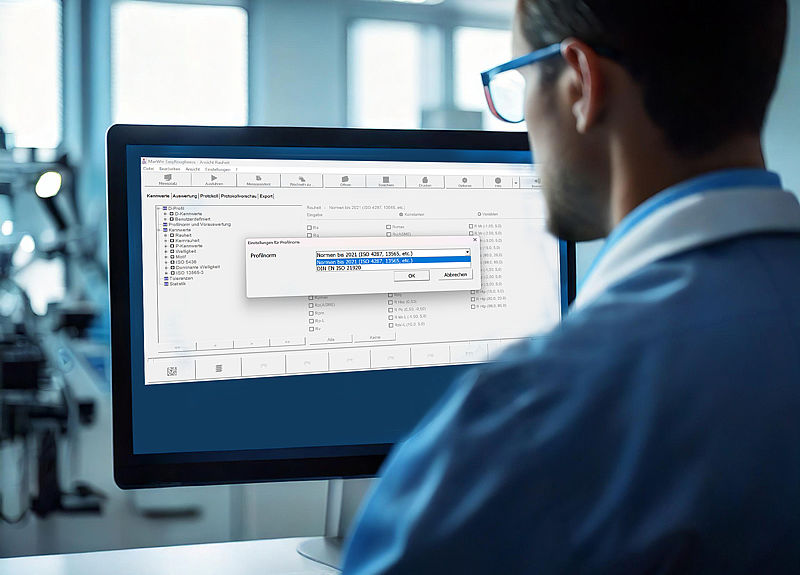

This is why the metrology specialists at Mahr have now updated their tried-and-tested MarWin software: “It fully maps the new surface standard ISO 21920, so that future-proof measurement and testing is guaranteed,” explains Michaela Sander, Product Management MarWin.

However, as practice shows, the innovations have not yet become established in companies' quality assurance systems. The same applies to design engineers, who are often not yet familiar with the new surface standard.

Only when the quality assurance department receives a workpiece whose drawings contain the new drawing entries is it bound by the new standard. “Because the changeover will still take some time, MarWin will continue to offer the previous ISO 4287 and 13565 standards for use in the software. Users simply press a button to select which version of the standard they want to work with - until ISO 21920 is fully established,” explains Sander.

Launched by international teams

The MarWin software platform offers users in research, quality assurance and production important tools that make quality assurance more efficient and economical. It has already established itself as measurement and evaluation software in over 60 countries and is ideal for Industry 4.0 manufacturing companies, in which measurements and tests are becoming increasingly automated and networked.

The new standard was launched by international teams of experts. As an international metrology manufacturer, Mahr was involved at project manager level and is familiar with every detail that has changed compared to the various previous standards. “With the new MarWin version from Mahr, users in quality assurance are therefore on the safe side: it guarantees DIN-compliant measurements and ensures the future viability of every production,” summarizes Vanessa Becker, Product Manager for MarSurf.