Métrologie de haute qualité pour le contrôle de la qualité en salle de mesure, en production, à la réception des marchandises et lors du développement.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

Guidages à billes de haute précision pour des mouvements de déplacement vertical et de rotation sans jeu dans la construction mécanique et d'équipements.

Métrologie innovante pour de nombreuses applications :

- • Longueur et diamètre

- • Surface et contour

- • Forme et position

- • Dentures et arbres

Mélange et dosage précis de liquides et de pâtes :

- • Pompes de dosage à engrenages

- • Pompes à filer

- • Mélangeuses et doseuses et têtes de mélange

Guidages à billes pour des mouvements linéaires et rotatifs sans jeu dans les domaines suivants :

- • Construction mécanique

- • Mécanique de précision

- • Optique

- • Électronique

- •Et de nombreux autres secteurs

As an internationally active company, Mahr holds its patents not only in Germany, but worldwide.

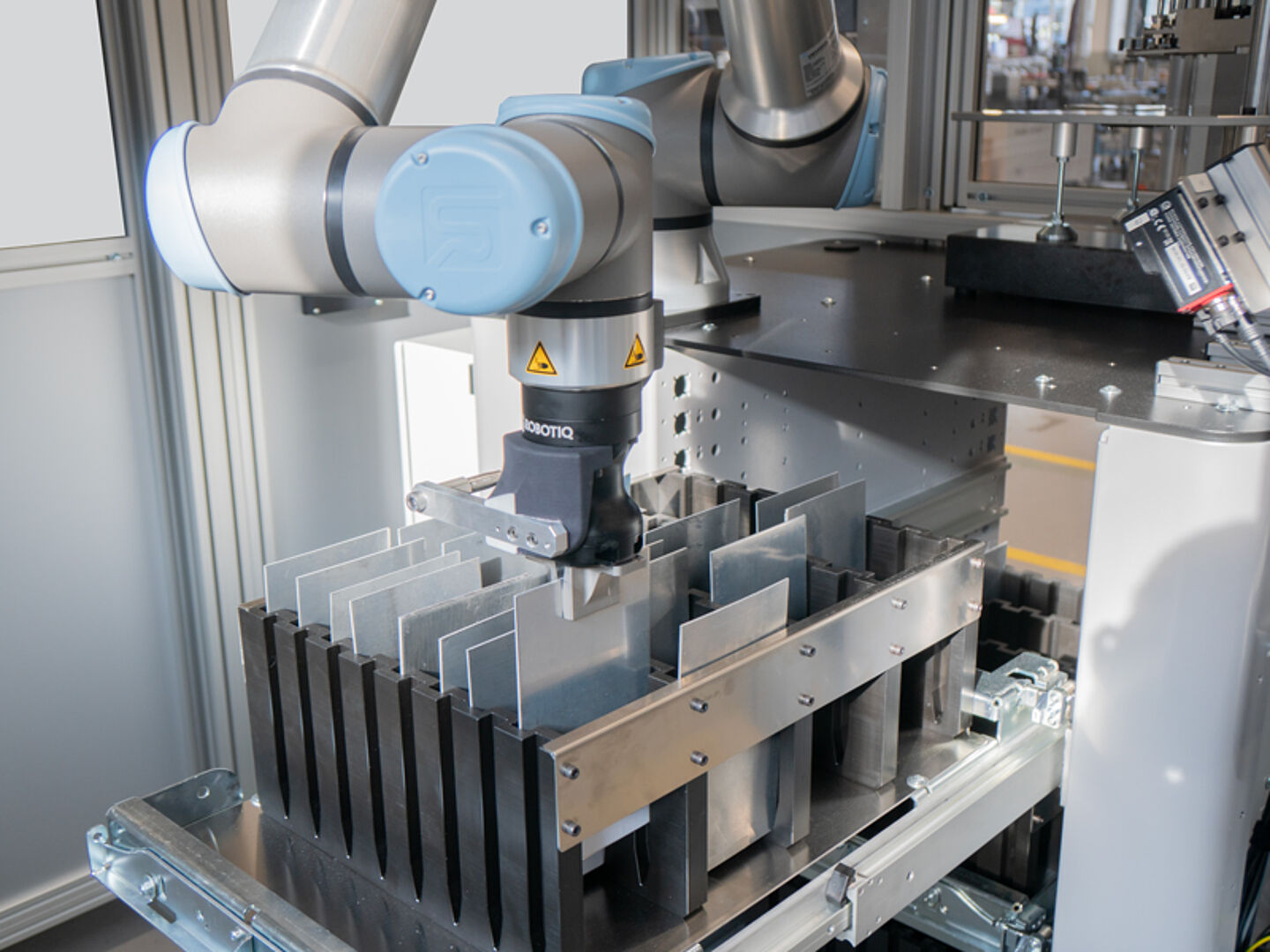

Automation solution for aluminum sheets

The two main components of the MES measuring station are, firstly, four MarSurf M 310 roughness measuring devices, which are actually mobile and combined in a special design as a stationary unit. They each have a double-skidded probe system. This means they meet the roughness standard applicable to sheet metal in accordance with DIN EN 10049:2014-03 and can measure the required roughness of Ra 0.25 µm.

Secondly, the measuring station is equipped with a collaborative robot including workpiece storage, the so-called Mahr Feeder. This automatically removes the sheet metal samples from the magazine, scans the applied QR code for identification and documentation and positions them in the measuring device. The samples are then measured from both sides and either approved or rejected depending on the result.

The advantages of this solution for the customer are manifold:

- By measuring only a very small sample, the customer can make a reliable quality statement for the entire coil.

- No personnel is required for measuring. An operator is only required to reload the samples into the workpiece storage.

- The service life of the measuring station is increased and even three-shift operation is possible.

- Overall, this increases throughput while reducing costs.

Further information on this topic can be found here:

- Would you like to realize your own project realize your own project with us? Find out more on our website.

- Click here for the product portfolio of Mahr Engineered Solutions.

- You can watch a video about the Mahr Feeder here.