From a simple measurement program to a comprehensive test plan

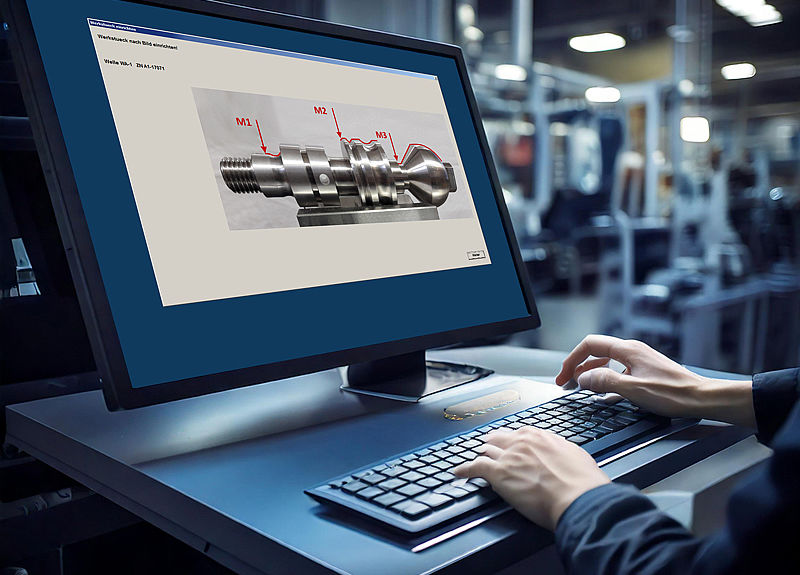

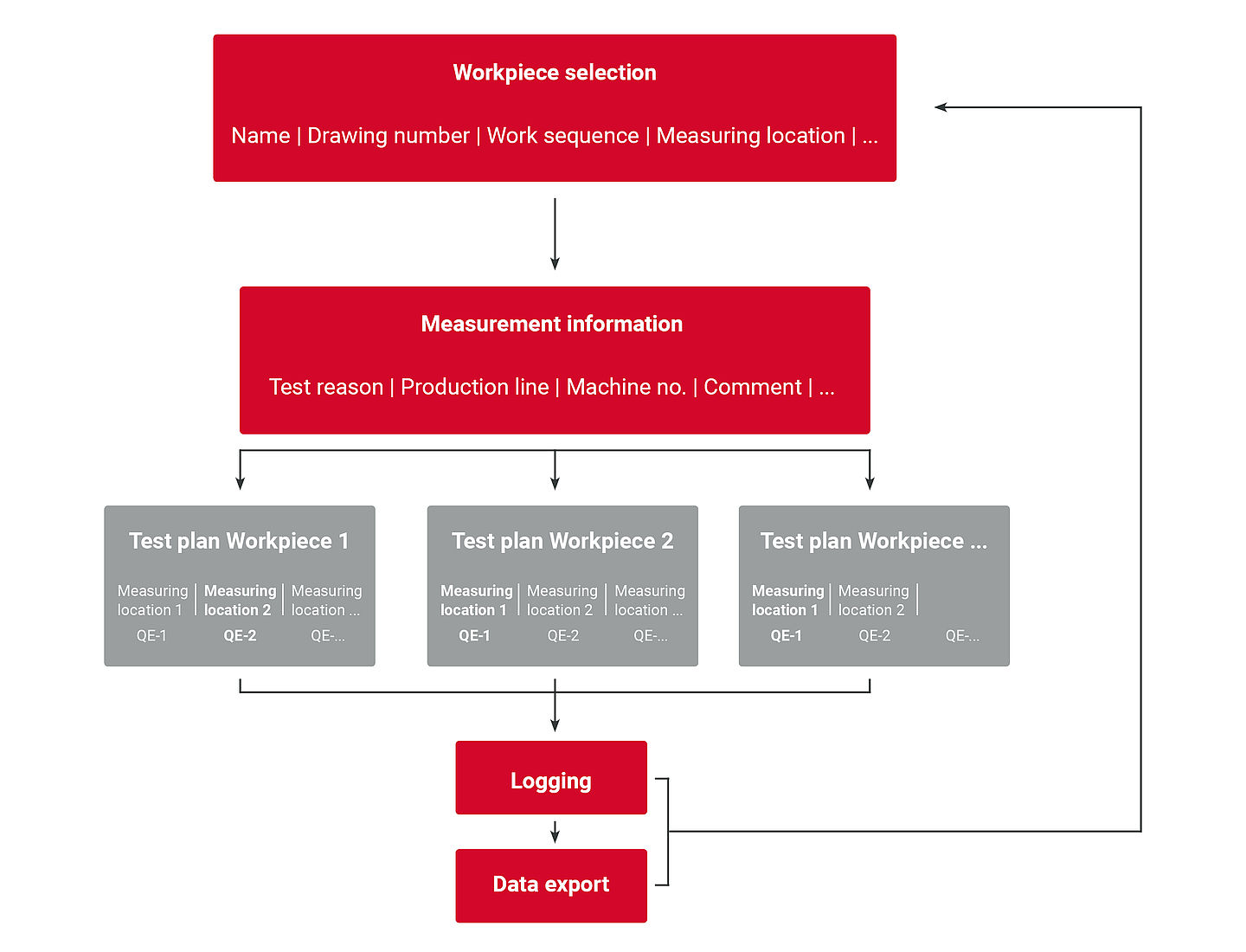

This is very easy with the MarSurf QE operator guidance system from Mahr, which can be used to combine various measurement programs into a test plan. This then takes on the task of "job management" for recurring measurement tasks. The program "Operator guidanceMarSurf QE" program supports data input as well as guidance and instructions for the individual steps of the entire test sequence. "The operator guidance can be designed universally so that both roughness measurements and contour measurements with different drive units are possible within a test plan," explains Jakob Schlie, Application Engineer at Mahr. "All protocol data can be easily selected via pull-down menus or – even more conveniently – via a DMC code reader. Incorrect entries are therefore impossible." In addition to the existing selection menus, fields for individual texts can be created and the input masks can be adapted to the respective requirements and dependencies of the production processes. "This means that even extensive inspection plans can be easily created by calling up and executing several MarSurf Quick & Easy measurement programs one after the other," says Schlie.

Extremely simple creation of inspection plans

The creation of an inspection plan is extremely simple: Users create a new plan in the "Inspection plan management" screen and then select the previously created Quick & Easy measuring programs that define the program sequence. The new test plan is displayed in the "Test plans" menu. A test plan can contain a single, several or a dozen Quick & Easy measurement programs, so that even very extensive program sequences are possible. The individual programs are clearly displayed in a table and their sequence can be changed at any time.

Optional probe arm management

Users start the "MarSurf QE operator guidance" program either from the contour view (MarWin EasyContour) or from the roughness view (MarWin EasyRoughness) via a function key. All entries and workpiece-specific data from the input screen are saved so that they can be added to the measurement reports after the measurements and used for data export. "Users can then use this information to create file paths and file names in order to store the measurement results and reports in an organized manner," says the application engineer. If the probe arm database is used, the available probe arms or drive units can also be selected directly for the respective Quick & Easy program. The measurements are counted while the measuring station is in use. Once the number of measurements defined by the administrator has been reached, the operator is signaled that a control measurement must be carried out to check the measuring station. Alternatively, a time interval (e.g. 7 days) can be entered after which the control measurement is to be carried out. The software runs under MarWin, can be retrofitted to all PC-based MarSurf measuring stations and thus improves performance in quality management.

Key functionalities at a glance

The software for MarSurf measuring stations manages Quick & Easy (QE) measuring programs to simplify job management:

- Dialog-based creation and selection of measurement sequences from QE measurement programs based on customer-specific data structure

- Input of additional data with transfer to protocol header or qs-STAT

- qs-STAT and pdf export at the end of the entire measurement sequence

- Storage of program sequences for checking the measuring station and the probe arms

- Can be retrofitted to all MarSurf measuring stations