Premiere at Control 2025: Mahr presents comprehensive scattered light portfolio for the first time

Mahr acquired OptoSurf GmbH from Ettlingen in 2024 – a major step towards the future. By implementing the OptoSurf portfolio, the leading metrology manufacturer is opening up new opportunities in the field of tribology. This gives Mahr customers a further plus in cutting-edge technology. The Göttingen-based company will be presenting the following scattered light technology product ranges at its stand 3104 and 3204/Hall 3 at this year's Control:

▶ MarSurf3D Sensor OS 500

Whether for grinding or finishing machines, rollers, steel sheets or roller bearings: the OS 500 scattered light sensor can be integrated into machine control systems and measures exactly where it matters: directly inline. The device is extremely fast, low-maintenance, robust and precise. It is controlled remotely and can evaluate roughness and waviness using the software provided. The 8 kHz version of the OS 500 scattered light sensor is designed for large surface measurements such as rollers.

▶ MarSurf3D OptoRack

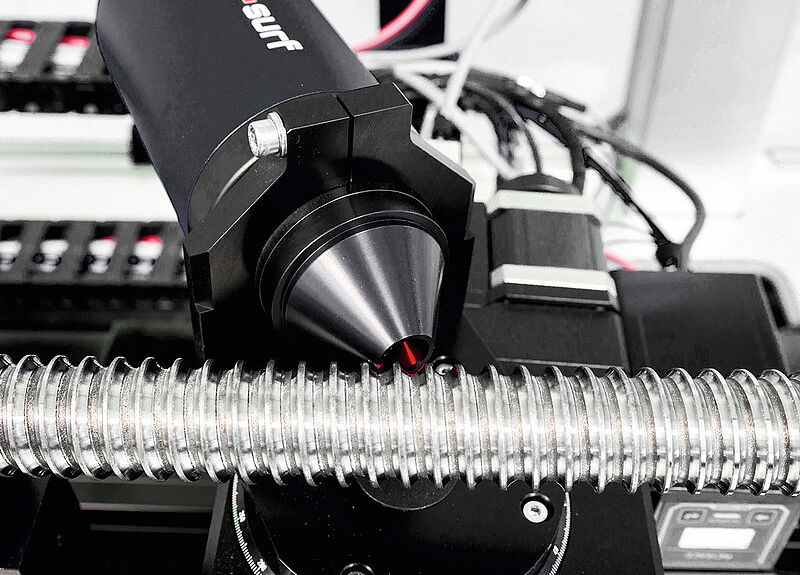

Ball screw drives are used to convert rotary motion into longitudinal motion – for example in machine tools and steering systems. Particularly in the latter, efficiency, wear and possible noise development depend heavily on the surface quality of the ball tracks. This is where the OptoRack measuring machine really comes into its own: It was specially developed for process monitoring during the grinding and finishing of racks and ball screws. Thanks to a swivel axis, the sensor can measure the roughness and waviness separately on paths to the right and left of the pressure point of the raceways at any point on the spindle.

▶ MarSurf3D OptoWorm

The worm gear is of particular importance in electric power steering systems. This is because the demands on the surface of the worm flanks are extremely high due to the force that is transmitted to the worm gear. The OptoWorm measuring device was specially developed for process monitoring in the precision machining of worm gears. The machine makes it possible to measure the entire functional surface of the left and right flank.

MarSurf3D OptoShaft

▶ Finished bearing seats that rotate in the gearbox or motor as needle bearings place high demands on the surface quality: even the smallest waviness with amplitudes < 0.05 μm lead to intolerable noise. The waviness is caused by chatter marks on the bearing seat, which occur sporadically during the grinding process and are not completely removed after finishing. With the OptoShaft, the processes involved in grinding and finishing the bearing seats can be monitored in real time. The highlight: thanks to the extremely robust and precise scattered light sensor, the measuring device can be used directly next to the production machine.

For Mahr, the addition of OptoSurf scattered light metrology is an ideal complement to the existing systems. Thanks to the robust and precise technology, surface parameters can be measured extremely accurately and efficiently in harsh production environments.

>> Save the date: 37th Control in Stuttgart |May 6-9, 2025

>> Visit us at booth 3104 and 3204 in hall 3 – we look forward to seeing you there!

Make a note now: High Performance Surface Summit (HPS) 2025 in Göttingen

Make a note of this date now: The High Performance Surface Summit will take place in Göttingen on October 7 and 8, 2025. We invite you to an event that brings together experts from science and industry on the topic of scattered light technology. What are the requirements for mechanical surfaces of the future? How can they be produced and measured? So stay tuned, we will inform you about the details as soon as possible!